Thermal Sticker

Thermal Sticker

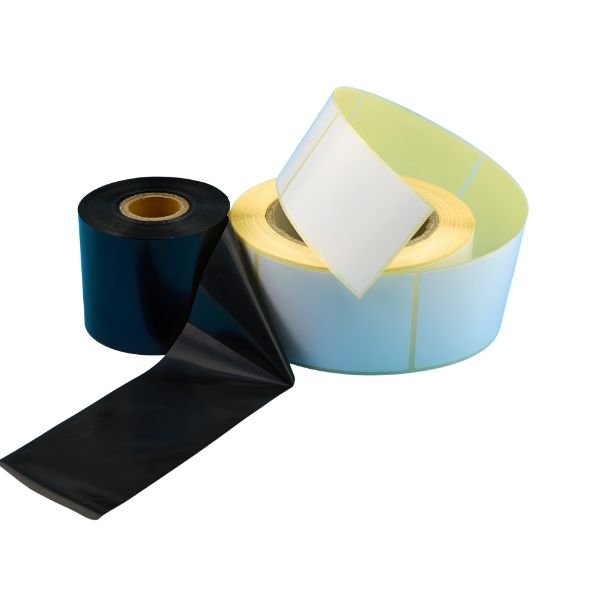

Material: Thermal Paper or film with a heat-sensitive coating that reacts to heat for imaging.

Printing: Designed for Direct Thermal Printers, which create the image using heat only, eliminating the need for ink or ribbons.

Adhesive: Features a strong, pressure-sensitive adhesive to ensure reliable and long-term sticking to various surfaces.

Format: Supplied on rolls, pre-cut into various multi sizes to fit different applications (e.g., shipping labels, shelf tags).-

The advantages of your thermal stickers revolve around operational speed, efficiency, and print accuracy in commercial settings:

-

High-Speed Labeling: Thermal printing is incredibly fast, allowing for rapid generation of labels and stickers. This is critical for high-throughput environments like warehouses and e-commerce fulfillment centers.

-

Cost-Effective Printing: By eliminating the need for ink, toner, or thermal transfer ribbons (in direct thermal mode), the thermal stickers provide a lower overall cost per printed label.

-

Superior Readability (Scanning): Thermal printing produces very sharp, high-contrast barcodes and text. This excellent clarity ensures high scan rates and minimizes errors in inventory, point-of-sale, and shipping processes.

-

Reliable Adhesion: The strong adhesive ensures that the labels stay firmly attached to packaging, boxes, or products, preventing loss of vital tracking or pricing information during transit.

-

Low Maintenance: Thermal printers are generally more robust and require less maintenance than traditional printers, contributing to a smoother, more reliable labeling workflow

-

-